Advanced expertise in simulation and testing to design better, faster, and with greater confidence.

Master dynamic behavior to boost performance

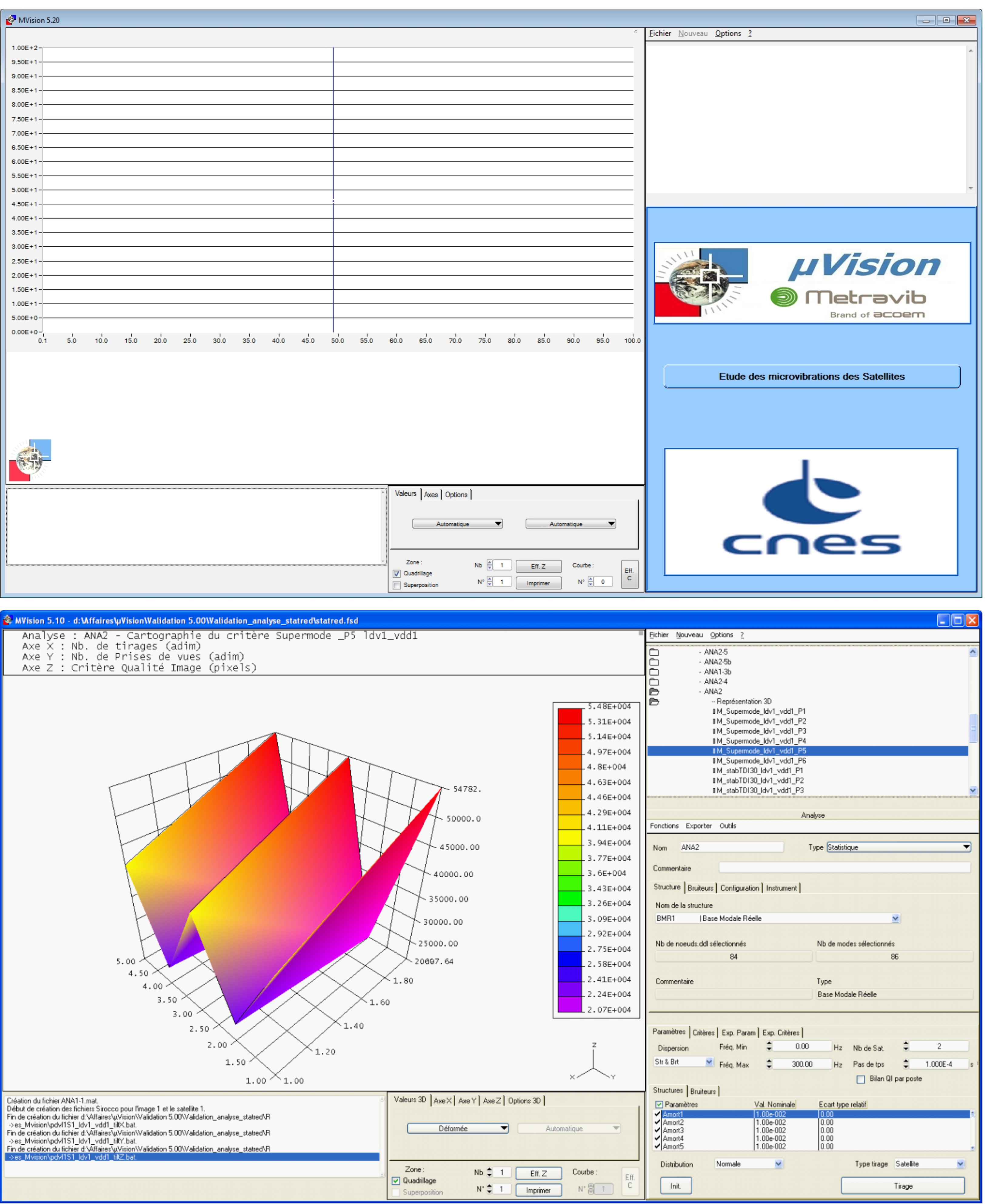

From initial design to final validation, Metravib Engineering supports your most demanding projects with recognized expertise in numerical simulation and experimental testing.

Our skills in structural dynamics, vibration, and acoustics allow us to anticipate, optimize, and validate the behavior of complex mechanical systems before testing or industrialization phases.

By combining finite element analysis (FEA) with physical testing, we deliver reliable results that accelerate development, reduce risks, and limit prototyping costs.